The Critical Path Method (CPM) of construction scheduling is a popular method to set the timeline, analyze it to determine the most critical tasks that most affect the scheduled completion date, and reduce the impact of delays.

No successful construction project begins without a schedule. Construction project schedules determine key dates, like equipment delivery, inspections, and final completion. If the schedule isn’t accurate and complete, it can create both project and payment delays.

Using schedule analysis methods like the critical path method allows project team members to identify key tasks and workflows that could potentially delay completion and payment. When changes are made that affect these key tasks, contractors can ask for more time and compensation, if allowed by their contract.

How to calculate the critical path schedule in construction

Critical path method (CPM) scheduling focuses on identifying critical tasks that cannot be delayed without changing the overall schedule. CPM is the standard scheduling process used to illustrate delays in construction litigation, so it’s important for every contractor to understand it.

The critical path method process identifies the minimum completion time for the project, based on the tasks, their durations, and their interdependencies. It’s the longest path in duration from the beginning of the project to completion.

1. Identify all tasks

Start by identifying all the tasks in the project, being as detailed as possible. Using a work breakdown structure (WBS), which is a hierarchical representation of all the deliverables in a project, can help break down the tasks into manageable pieces.

For example, the steps for installing a roof include installing underlayment, insulation, ice/water shield, flashings, shingles, and caps. Each of these steps would be a separate activity in a CPM schedule.

2. Determine the order of tasks

Then arrange the tasks by the order they need to be completed. When identifying predecessors and successors for each task, ask:

- What needs to happen before this task?

- What can be started after this task?

- What tasks can be done at the same time?

In our roof example, the tasks were listed above in the order they need to be completed. The shingles cannot be installed until after the ice/water shield is in place.

When determining the order of the tasks, start to look for dependencies — what has to happen before a certain task can start. These dependencies create the connections between tasks and provide the workflow logic for determining the critical path.

When installing a roof, the underlayment has to be completely installed before insulation can be installed in an area. If the roof is large enough, the work can be phased so that insulation can be installed in an area once the underlayment is complete there. This phasing of work is one way to reduce the overall scheduled time.

3. Identify the time required for each task

Next, determine the minimum amount of time it will take for each task to be completed. These durations will be estimates based on the amount of work and the availability of resources like materials and labor. Past projects are the best resource for determining how long a particular task will take.

4. Set start & finish times

Now it’s time to determine the critical path for the project. This is done by determining the earliest and latest dates each task can start and be finished, based on the duration of each task and the dependencies identified.

Early start, early finish

A forward pass through the schedule is conducted to determine the early start and early finish dates for each task. These dates are the earliest a task can start and finish, based on completion of the tasks previous to it.

For example, if the installation of underlayment takes five days, the earliest that insulation (the next task) can start is day five. If insulation takes three days, the earliest it can finish is day eight (early start on day five, plus three days).

If there are other tasks that need to be completed before the insulation can be installed, then the earliest it can start will depend on the completion of those other tasks.

Late start, late finish

Once all the early start and finish dates have been determined for each task, then a backward pass is performed to calculate the late start and late finish dates for each task. These are calculated in the same way as the forward pass, except durations are subtracted instead of added.

For example, if the roof cap takes one day to install and the completion date is day 10, then the latest it can start is day nine. If the shingles take three days to install, the latest they can start is day six, and the latest they can finish is day nine (subtract three days from day nine, the latest the shingles can finish).

5. Calculate the slack

Slack, or float, is determined by taking the difference between the early and late start or finish dates. If there is a difference between these dates, that’s the amount of time the task can be delayed without affecting the overall schedule.

If the slack or float is zero, then the task is on the critical path.

Creating the critical path diagram

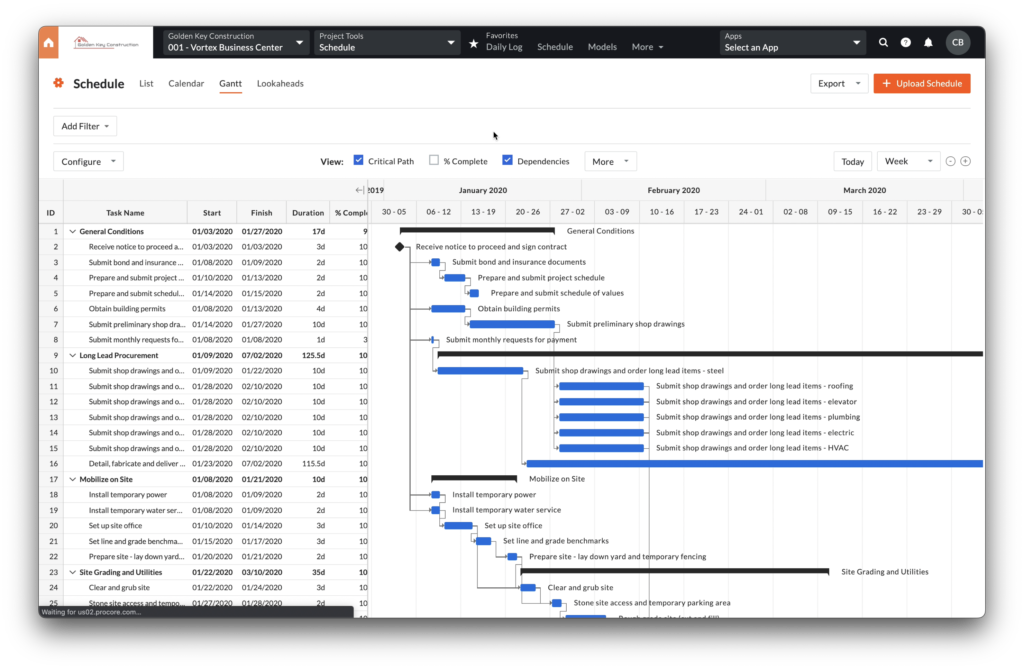

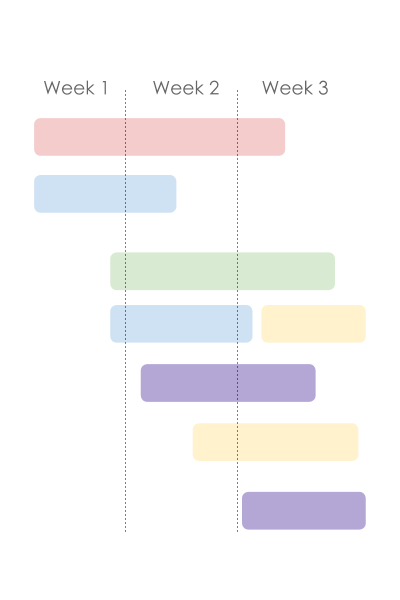

The critical path diagram is a visual flow of the milestones that are critical to the project’s success. There are many diagram styles to represent the critical path, but ultimately the goal is to communicate the plan effectively, and make sure that it’s useful towards executing the project. Software programs can also automate calculations and simplify the creation of a critical path diagram. Here’s an example of what a finished critical path diagram looks like.

Use a free construction schedule template

Download free construction schedule templates for everything from managing projects to tracking payments and submittals.

Benefits of critical path method for construction

The critical path method for construction has many benefits that have led it to become one of the most traditionally accepted methods of scheduling. Here are a few of them:

- Industry familiarity: Well known and embedded in the industry, so you won’t have to teach it in most cases

- Visualization: The diagram is an easy to understand visual path that anyone on the project can use to avoid steering off course or focusing on non-critical steps

- Sticks to established schedules: As a “push” method of construction scheduling, materials and resources will be delivered on time according to established dates

- Forward thinking: Delays can be built into a schedule in order to keep critical tasks from impacting the project’s completion time

Some critics suggest this method doesn’t put enough emphasis on the connection between critical tasks and the prerequisite tasks that are needed to proceed, or collaboration between the groups responsible for executing them–cornerstones of the pull planning method.

Read more: Pull Planning in Construction

In order to avoid major delays, rework, and waste caused by missing critical path deadlines, it’s important to work closely with the responsible teams to anticipate potential delays of prerequisite tasks and build enough slack into the schedule.

Dealing with schedule delays and changes

Almost every construction project has schedule delays of some type. Materials are delayed or workers get pulled off the project to work on another one. Both of these incidents affect the duration of tasks on the schedule. If the task is on the critical path or is more than the slack for that task, the overall completion date for the project can be affected.

Related reading: Who pays for a construction delay?

There are a couple of ways to deal with delays to tasks on the critical path: crashing and fast-tracking.

Crashing means adding resources to decrease the duration of a task. Adding workers or working overtime are ways of adding resources to shorten a task’s duration.

Fast-tracking involves performing critical path tasks simultaneously to shorten their durations. This can be done with tasks that aren’t direct predecessors or successors, otherwise, this strategy wouldn’t work.

Fast-tracking is often done when work is phased to allow critical path tasks to be performed in different areas simultaneously.

Advantages of CPM construction scheduling software

Most project managers aren’t performing hand calculations to determine the critical path of their projects. Today’s construction scheduling software packages make running a CPM analysis quick and easy.

Some of the most popular software platforms for construction scheduling include Procore, BuilderTrend, and CoConstruct.

Software reduces the chance of math errors when calculating durations and start and finish times. It also helps PMs identify the critical path quickly, saving time, particularly on large projects. The software also quickly updates the schedule and the critical path when there is an update to the schedule.

Analysis of delays and the effect of crashing or fast-tracking can be seen almost instantaneously. It also helps quantify the amount of float for each task, allowing PMs to know what tasks can slip without affecting the overall completion time.

One thing that software cannot address is inaccurate information. If there are missing tasks or the duration of tasks is incorrect, the schedule won’t be accurate. This is why it’s important to have several team members review the schedule before identifying the critical path. A continual review process will help keep the schedule on track and avoid errors.

The critical path method is important for everyone

Whether you are a general contractor or subcontractor, it’s important to know which of the tasks in a project are critical to its completion. When delays or other changes are made that affect these critical tasks, then you can quickly identify potential effects to the overall project completion timeline. Documenting and quantifying these delays are important when it comes to proving requests for added costs and time.

Even if you don’t perform the manual calculations to determine the critical path, it’s important to understand the process so you know what affects those tasks and their completion. Creating a thorough, accurate schedule is vitally important to showing the effects of changes and proving claims for added time and costs.