A good construction schedule is a crucial step toward finishing your project on time and on budget. Construction schedules should provide a clear picture of project timeframes and milestones, should be updated to track progress, and should be able to show what still needs to be completed.

How are you keeping your project on schedule? Knowing how to create a construction schedule is key to keeping everyone on track. Let’s take a look at a few of the more popular methods of creating a construction schedule.

Importance of a Good Construction Schedule

A construction project is essentially just a collection of smaller, individual projects. Coordinating all of these tasks and personnel required for each can cause headaches for even the most highly regarded contractors and project managers. A well-formulated construction schedule can help balance all these different moving parts on a job site.

Gone are the days of “shooting from the hip” in hopes that everything gets done. Everyone on a project is trying to avoid delays. Unfortunately, delays are inevitable, but delays caused by poor scheduling increases tension and sours business relationships quickly.

There are many simple options available for scheduling a project. However, the larger and more complex the project, the more the need for a formal, detailed schedule increases. By implementing detailed, easy-to-use construction schedules, suppliers know when to deliver, subs know when to schedule their laborers, and GCs and stakeholders can quickly identify the progress of the overall project.

Use a free construction schedule template

Download free construction schedule templates for everything from managing projects to tracking payments and submittals.

Questions That Need Answers

Managing an updated and accurate construction schedule increases communication on the project and ensures successful completion. Therefore, before you start work on any given project, there should be dozens of questions running through your head that need to be answered.

- What tasks need to be done?

- When and in what order?

- How long will each task take?

- What resources are needed for each task?

- Who has the knowledge/skill/time to do each task?

- What dependencies exist between tasks?

- What are the project milestones and what work will be done at that point?

If the construction schedule can’t answer most (if not all) of these questions, that schedule might not be sufficient to keep the project organized and to track progress.

Methods for Creating a Construction Schedule

The following are some common methods for creating a project schedule.

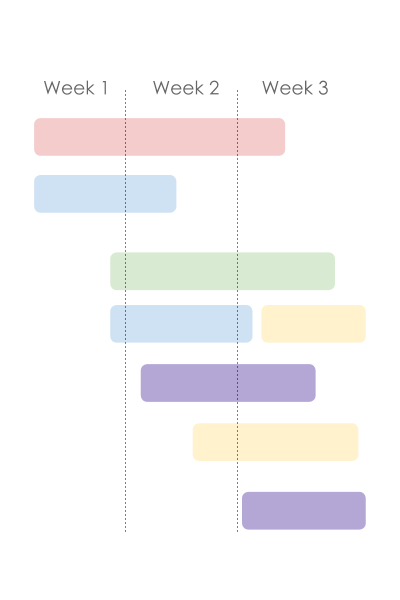

Bar Charts

This is the simplest and easiest way to generate construction schedules. The most popular form of bar charts is known as a Gantt chart. Bar charts will have the project timeline shown at the top. Each activity is represented by a bar showing the start date and time of completion, listed in chronological order. Bar charts can also be useful to monitor the number of resources needed for each individual activity.

Pros

Bar charts, like the Gantt chart, are simple, and they’re easy to understand. Project tasks are clearly visible, making it easier to conceptualize what needs to happen at every stage of the project. This also makes it shareable – so, a project manager or prime contractor can easily get their lower tiered participants on the same page. What’s more, a well-organized Gantt chart will also make it clear what resources are needed for every task, too.

Cons

Construction projects are complex. So, visually representing each task via a bar chart can get complex pretty quickly. Further, while the bars on a bar chart or Gantt chart may represent the time for each task – they might not be able to provide a clear picture of what level of work will be implicated.

For More on Gantt Charts, ProjectManager.com has This Resource: The Ultimate Guide to Gantt Charts

Critical Path Method (CPM)

A critical path method schedule is a much more detailed sheet. It will show all the various activities and their dependencies on one another, useful for projects that include some level of unpredictability. The CPM will take into account the best case and worst case timelines for each activity. This diagram will also identify which activities must be completed at a certain time as to not affect the overall project deadline. This is what is known as the “critical path.”

Pros

Like the bar charts described above, the critical path method is relatively easy to implement. It also does a great job of identifying important points of the project – points where, if not managed properly, delays could take place. The critical path method also makes it easy to compare realities with expectations since project timelines are predicted and clearly communicated from the jump. Plus, because this method identifies potential choke points for the project schedule, it makes it easier for the project manager and/or prime contractor to make the hard decisions that might affect a project’s timeline.

Cons

Perhaps the biggest problem with the critical path method might be that it does little to show the allocation of resources and workflows – it focuses pretty narrowly on time. That makes CPM less than ideal for repetitive projects. Like with other scheduling techniques, for large and complex projects, utilizing the critical path method will get tricky. Plus, without the help of software solutions, it can be hard to track progress throughout the life of the job. Finally, it’s also hard to adjust on the fly with the critical path method if that path is thrown off – and it may take time to regroup and redraw the critical path. But again – software can help to alleviate this burden.

For More on Critical Path, Levelset has This Article: The Critical Path Method Creates More Efficient Construction Schedules

Line of Balance (LOB)

This linear scheduling method is ideal for repetitive construction projects, such as roadways or condominiums. Since repetitive builds are predictable as far as timing is concerned, this method (which is adapted from the manufacturing industry) focuses on resource allocation. Specifically, it helps to allocate resources that must be shared among crews or teams. That way, work can be performed on parallel tracks, and the unavailability of a particular resource (like equipment) won’t keep the job from moving forward. This prevents delays by ensuring the right amount of resources are available for each step, so the following ones are not delayed.

Pros

As mentioned above, the line of balance method can really come in handy when there’s repetitive work. Unlike the bar chart and critical path methods described above, line of balance focuses in on resource management – so, resources are maximized and shared among teams that need them.

Cons

When work is less repetitive, using the LOB method doesn’t make much sense. Focusing on the sharing and maximizing of resources will become less important if different crews are working on completely different tasks.

For More on Line of Balance, Designing Buildings Wiki has a Helpful Resource: Line of Balance

Q Scheduling

Q Scheduling is a relatively new technique that is gaining popularity. The Q actually means two different things: quantitative and queue. Quantitative refers to the quantities of resources (shown in bar chart format) that need to be used at different times and locations on the project. Queue refers to the sequence in which trades must pass through to be able to work on a project without interfering with one another. So, Q Scheduling is sort of like using the critical path method while also incorporating bar charts to represent material usage. It’s also been described as a version of the Line of Balance method that’s adjusted for non-repetitive projects.

Pros

Q scheduling, like the critical path method, does a good job of making sure no 2 tasks bump into each other causing delay. But, like the line of balance method, it also does a good job of allocating resources to these tasks, as needed. Further, unlike the LOB method, Q scheduling is effective on projects that don’t involve serious repetition. Thus, Q scheduling also replicates some of the benefits gained from using bar charts, too.

Cons

Q scheduling is a relatively new method for creating a construction schedule. It seems to incorporate many of the strengths of other project scheduling methods, and there isn’t much literature on the downside to Q scheduling yet. Still, it’s obvious that Q scheduling will take a lot of front-end effort to establish the construction schedule. But it seems like the effort at the start of the job will pay off when there are a high number of tasks and resources to manage.

Related Resources

- Lean Construction Promotes Efficiency

- Watch out for ‘No Damages for Delay’ Clauses | Construction Contracts