One of the mantras of the construction industry is “on time, on budget.” Project teams are always working against the clock trying to meet schedule milestones to ensure that a project is finished on time. Creating a project schedule at the beginning allows teams to think through the entire construction process and properly allocate their resources.

Most project teams develop a schedule by assigning a duration to each task. This duration is the time they think it will take to complete the task. But this fails to take into consideration the potential for delays — and the possibility that the work might be completed sooner than expected.

Standard Gantt chart schedules don’t include this level of analysis. But a PERT schedule provides a way for teams to take the best and worst cases into consideration early in the project.

What is PERT?

Program Evaluation and Review Technique, or PERT, is a process used by construction project teams to provide an initial schedule for a complicated project. A PERT schedule is created before the start of the project.

The process starts by identifying tasks in the project and their durations. Then, calculations are performed to provide the team with the best estimate of the time required to complete each task. Project managers can then identify critical tasks that need to be completed on time to keep the project on schedule.

Using a PERT chart

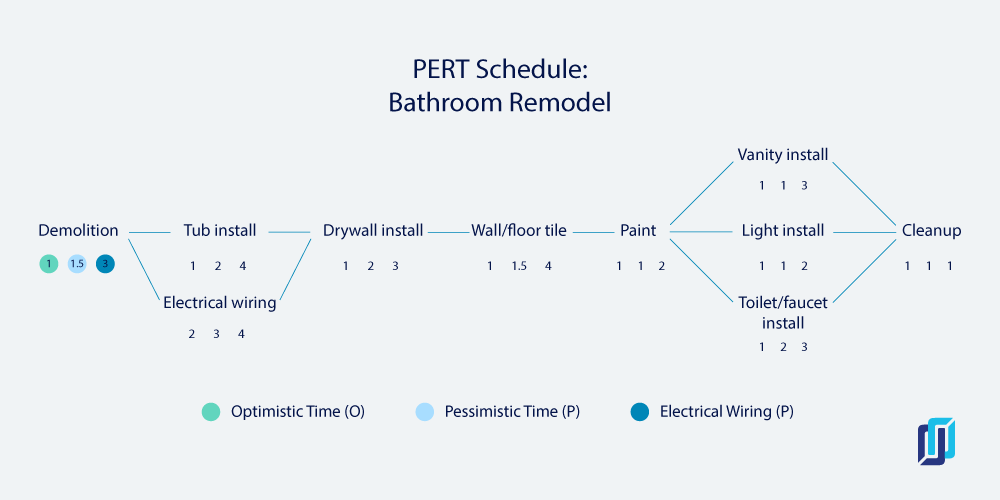

A PERT chart is a pictorial representation of the project schedule, similar to a Gantt chart. It shows the tasks that are required to complete the project, their sequencing, their dependencies, and their duration.

The PERT analysis (using the PERT formula) provides the durations for each task. Read on for more detail about calculating durations.

Here is a sample of a PERT chart created for a bathroom remodeling project.

The progress of tasks is shown by arrows going from one task to the next one in the sequence.

Boxes, or nodes, represent the completion of tasks or project milestones. Tasks that can be done simultaneously are shown with a split arrow leading to the next task down each path.

PERT vs CPM

PERT is used by project teams to develop an initial construction schedule for a project that hasn’t started yet. It’s used to help teams analyze the duration and dependency of tasks, and to identify critical items on the schedule.

It is also used on more complex projects with several simultaneous workflows to help project team members understand the relationships between the tasks.

The critical path method, or CPM, is a schedule calculation that allows teams to determine the most important tasks in a project. These tasks will delay the overall completion of the project if they are delayed in any way. Because of their effect on the completion date, they are considered critical tasks.

This analysis is usually performed on a project as it’s in progress, since critical tasks can change as the work moves along.

How to calculate PERT

PERT schedules are created by following these steps:

- Create a list of project tasks and milestones

- Put them in sequential order (simultaneous tasks are acceptable)

- Create the PERT diagram

- Determine the duration for each task using the PERT formula

- Determine the critical path tasks using the critical path method

Once you’ve created a list of project tasks and milestones, put them in the proper sequential order, and created the PERT diagram, the next step is to determine the durations using the PERT formula.

There are three durations that you need to determine for each task:

Optimistic time (O): The least amount of time it will take to complete a task. Assume everything goes well and you beat your estimated schedule.

Pessimistic time (P): The maximum amount of time it will take to complete the task. Think everything goes wrong; this is the worst-case scenario.

Most likely time (M): The best estimate of how long the task will take.

It’s probably easiest to come up with the most likely time first, and then figure out the optimistic and pessimistic times.

For example, if you have a large concrete pour that you know will most likely take three days, you could say your optimistic time was two days, and your pessimistic time was five days. Realistically, it will probably take three days, but the PERT schedule takes into account the fact that it may go faster — or everything may go wrong, and it could take longer.

Next, you employ the PERT formula to calculate the expected time (E), which is a more realistic estimate of the time for the task.

This new estimate takes the pessimistic and the optimistic timelines into consideration as well. The formula is:

E = (O + (4*M) + P) / 6

The calculation involves taking a weighted average of the three durations: optimistic (O), most likely (M), and pessimistic (P). To do this, add the durations, giving more weight to the most likely, and then divide them by the total number of factors we are looking at. This average is the weighted average time it will take for the task.

We start by adding the three times together, but multiply the most likely duration by four (since it is most likely to occur). We are weighting the average in our calculation, assuming the most likely time will happen four times more than the optimistic or pessimistic times.

Then, to get the average, we divide that total by six. The answer (E) is the expected duration for the task.

Let’s do the calculation for our concrete pour example:

- Optimistic duration (O): 2 days

- Most likely duration (M): 3 days

- Pessimistic duration (P): 5 days

(2 + 12 + 5) / 6 = 3.16 days

Based on our calculation, the concrete pour will take just over three days. This is just over our most likely time. Since we don’t expect everything to go totally right or totally wrong, this makes sense.

Once the durations for each task have been determined, the critical path can be calculated.

Why use PERT?

PERT is used when the duration of tasks isn’t clear — like when a project team is making the initial project schedule. Going through the process of PERT analysis helps the team organize the project tasks and visualize the complexity of the project and the task dependencies.

Another advantage is that it facilitates communication between contractors and subcontractors. Contractors seek feedback from their subcontractors regarding potential task durations. This allows them to discuss the schedule with them and determine the tasks that need to be complete before a sub can start work.

The PERT schedule is more flexible than a standard Gantt chart. Since it takes into consideration optimistic and pessimistic scenarios, it allows for a more thorough analysis of the critical path tasks and the effect of their delay on the schedule.

On the other hand, like any schedule, if the time estimates aren’t accurate for each task, the schedule is no good. Contractors need to work with their subcontractors to ensure that the initial durations are realistic.

The PERT method can take time. Performing a calculation for each task on a large, complicated project could take hours. Luckily, most scheduling software programs can perform the calculations for you.

Learn more: For more information on construction project scheduling — plus schedule templates and scheduling software recommendations — check out Free Construction Schedule Templates for Contractors.

Optimize a flexible schedule with PERT

Construction schedules are always tight, and they don’t offer much room for reality. Things happen, materials are delayed, and it affects all the tasks going forward.

A PERT schedule allows a project team to build some flexibility into their schedule, knowing that they have taken both the best-case scenario and the worst-case scenario into consideration. This analysis also helps the team break down the schedule and understand the task dependencies, which can help them identify tasks that can be done simultaneously or can be expedited.